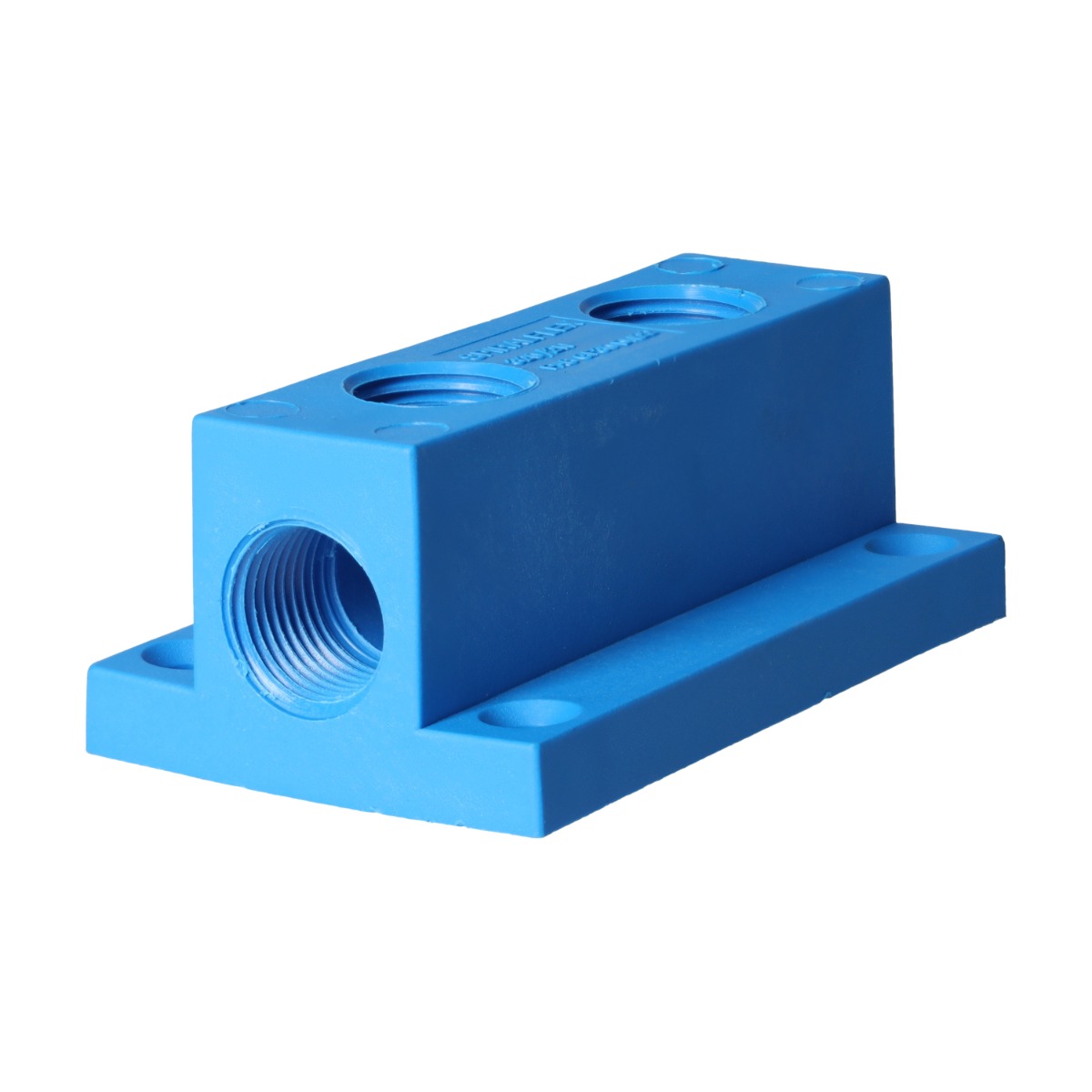

Air manifold, also known as a compressed air distribution rail, is a component of a pneumatic system that enables the distribution of compressed air to several connections. This allows multiple receivers (such as actuators or pneumatic tools) to be connected to a single power source, simplifying the installation and reducing the number of hoses and fittings required in the workshop. It is especially useful for more complex installations, where optimizing space and ease of assembly are important. The distribution rail is made of plastic. The use of a plastic distribution rail in pneumatic installations has several significant advantages: Lightweight: Plastic is much lighter than metal, making the installation and handling of system components easier. This is particularly important in areas where the weight of the entire installation matters, such as in systems mounted on ceilings or walls. Corrosion resistance: Plastic does not rust, making it ideal for use in humid or chemically aggressive environments. As a result, the plastic distribution rail has a longer lifespan and does not require as much maintenance as metal alternatives. Low cost: Compared to metal components, plastic distribution rails are often cheaper, which is advantageous for large installations where many distribution elements are needed. Safety: Plastic has low thermal and electrical conductivity, minimizing the risk of accidental short circuits and burns in places where the pneumatic installation may come into contact with other electrical components. High chemical resistance: Made from appropriate materials, plastic rails are resistant to many chemicals, making them suitable for installations that transport air contaminated with various fumes or chemicals. A plastic distribution rail is an attractive option in pneumatic installations due to its lightweight, corrosion resistance, low cost, and user safety.

Arvustused

Tooteülevaateid veel ei ole.